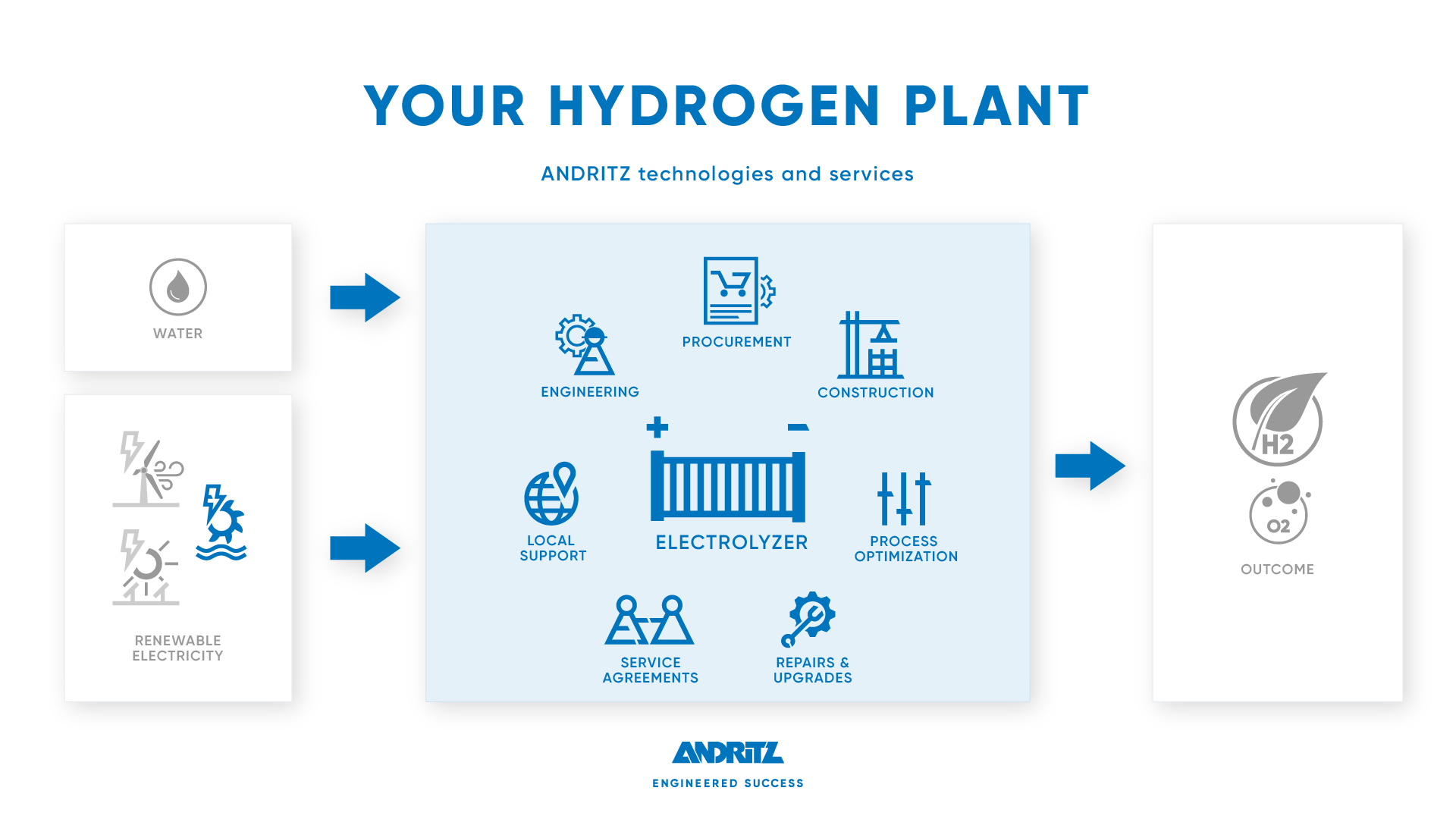

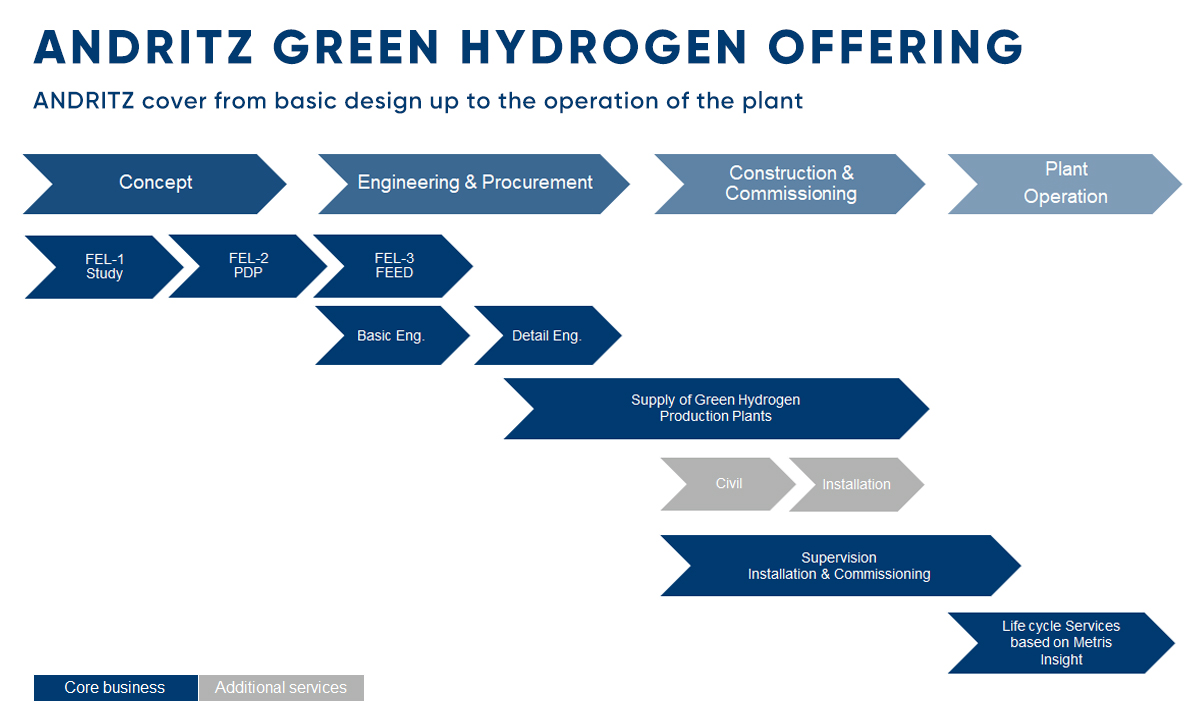

ANDRITZ is a leading provider of comprehensive solutions for Green Hydrogen production from consulting and engineering over plant building and EPC to life cycle services, including maintenance, supported by state-of-the-art digital solutions.

With our strong competence for electrochemical processes, global experience in turnkey and EPC and high competence in best-cost manufacturing over more than 170 years of experience, ANDRITZ provides the perfect setup required to deliver a safe, reliable and efficient hydrogen plant for your business.

ANDRITZ combines worldwide plant building experience as an EPC company, including design & engineering, civil and installation services in four core business areas – Pulp & Paper, Metals, Hydro and Separation.

Therefore, leveraging our extensive experience in EPC and turnkey projects, ANDRITZ is well-positioned to execute Green Hydrogen projects in targeted markets. We have the expertise to develop hydrogen plants based on AEL and PEM technologies, in addition to providing core equipment and associated services.